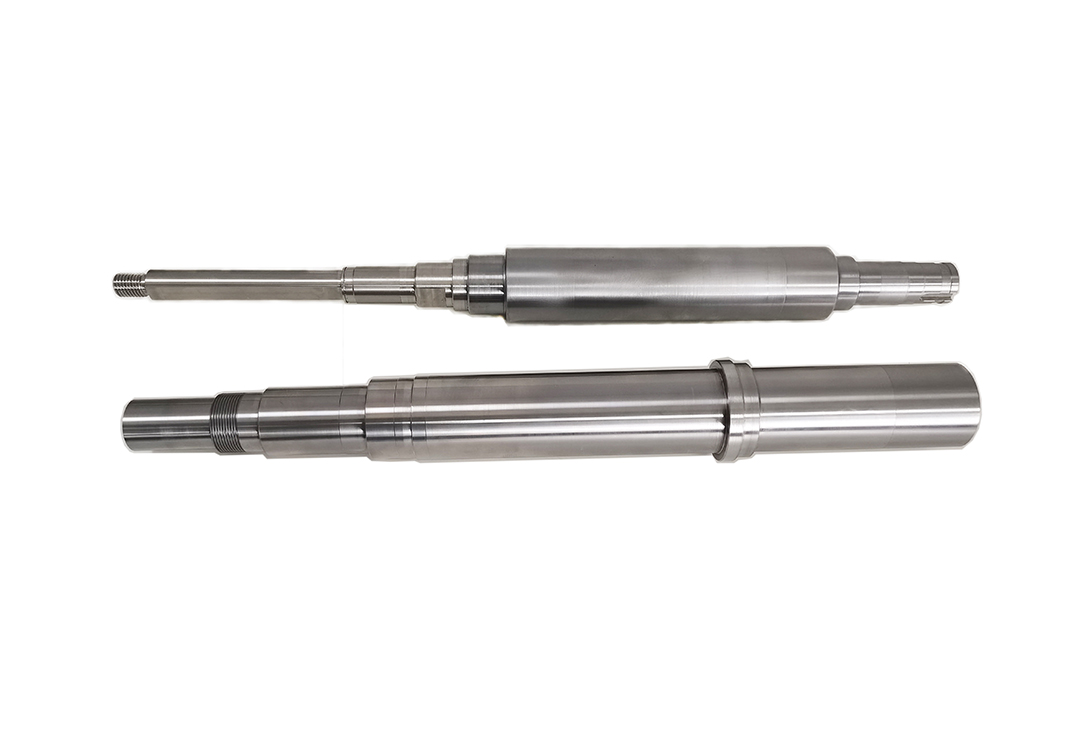

Slender shaft can easily get vibration marks in the process, also requires high precision control

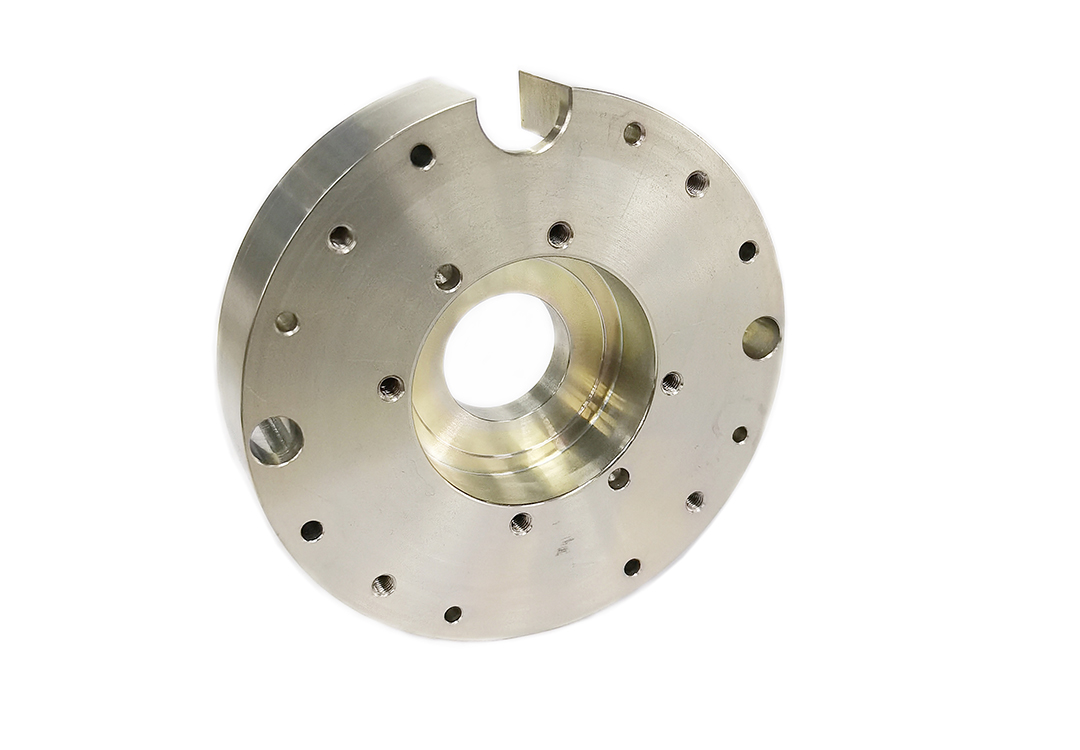

High precision requirements, soft material, strict geometric tolerance, deformation is hard to control, strict tolerance of inner hole.

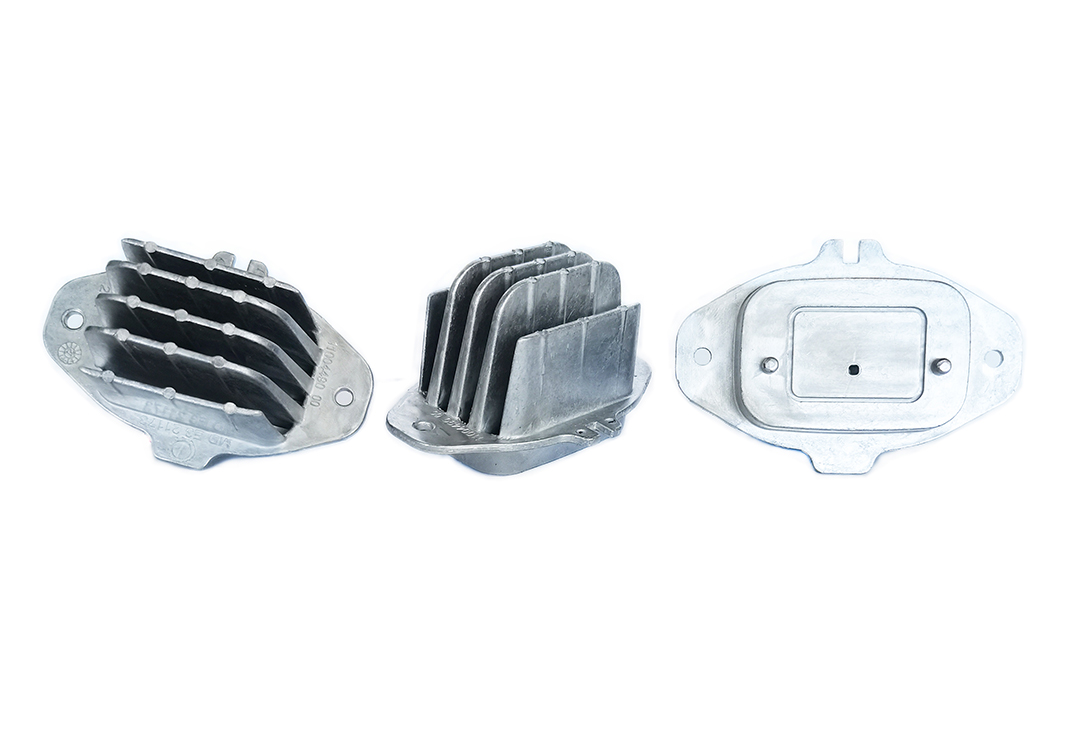

Use high-precision alloy steel profile as casting, the part structure is complex, the dimensional tolerance is strict, the processing needs to design special fixture.

It’s hard to produce, high precision, product diameter is small, easy to cause deformation during processing, the outer diameter tolerance is 0.009mm.

The producing process is complex, dimensional precision is high, processing is extremely difficult.

The product is the key part of the cylinder, the demand is large, the surface needs to be galvanized, after galvanized, the product surface quality requirements are strict.

The products are made by aluminum alloy profiles, the inner cavity structure is complex, and special fixture design is required during processing.

The bore diameter tolerance needs to meet 0.018mm after galvanized, and the processing is very difficult.

The production process is complex, the precision is high, the material is soft, and the geometric tolerance is strict, the deformation is hard to be controlled, and the tolerance of the inner hole is strict.

The processing is difficult, and the product has thin-wall, the minimum wall thickness is 1mm, which is easy to deform during clamping.

The production process needs to use CNC lathe, Machining center, CNC grinder together, to avoid the deformation of each process.

Product processing precision is very high, and the processing needs to design special fixture, and online measurement system to complete high-precision processing.

The geometric tolerance requirements are strict, processing needs to design special fixture, and processing accuracy is very high.

The product process is complex and difficult, the size requirements are high.

The geometric tolerance requirements are strict, and difficult to process.

High process complexity – the pulley groove is wide and deep, which requires special tooling to produce it efficiently and accurately.

The product processing precision is high, the processing needs to design special fixture, processing precision is high.

Product hardness requirements are extremely strict, internal thread, heat treatment process, high precision.

The product structure is complex, and the processing accuracy is very high. Special fixture should be designed during the processing. The product needs to do fully porosity test.

Complex product structure, and high processing difficulty and precision.

Products for assembly, with a variety of types and materials, high dimensional accuracy requirements, the assembly process is complex, and testing is extremely strict.

High precision requirements, various sizes, difficult processing.

Product structure is complex, processing difficulty is extremely high, very strict deburring requirements in through hole.

Complex process and high precision, hole position requirements are very strict.

Cavity is deep, and draft angel is small, and the assembling position of casting surface appearance requirements are very strict.

Complex process and high precision, hole location requirements are very strict.

Complex process and high precision, hole location requirements are very strict.

鲁ICP备14015069号-1 鲁公网安备 37028102000569号 Qingdao Fengguang Precision Machinery Co. LTD All rights reserved cnzz: